Introduction

This manual provides essential instructions for the safe and effective operation, setup, maintenance, and troubleshooting of your ESAB EMP 210 Multi-Process Welder. Please read this manual thoroughly before using the equipment to ensure proper function and safety.

1-сүрөт: The ESAB EMP 210 Multi-Process Welder shown with its complete set of accessories, including MIG gun, TIG torch, electrode holder, ground clamp, gas regulator, and welding wire spool. This image illustrates the comprehensive package provided for various welding applications.

Коопсуздук чаралары

Always prioritize safety when operating welding equipment. Failure to follow safety guidelines can result in serious injury or death. Refer to relevant safety standards and regulations in your region.

- Wear appropriate personal protective equipment (PPE), including welding helmet, gloves, protective clothing, and safety shoes.

- Ширетүүчү түтүндү дем алуудан сактануу үчүн жетиштүү желдетүүнү камсыз кылыңыз.

- Protect bystanders from arc rays and sparks.

- Never weld near flammable materials.

- Ensure proper grounding of the welding machine.

- Disconnect power before performing any maintenance or changing consumables.

Жайгашуу

1. Таңгактан чыгаруу жана текшерүү

Carefully remove the welder and all accessories from the packaging. Inspect for any shipping damage. Report any damage to your supplier immediately.

2. Power Connection

The ESAB EMP 210 operates on both 120V and 230V AC power. The machine automatically detects the input voltage. Ensure the power source is properly rated for the welder's requirements.

- 120V Иштетүү: Use a dedicated 20A circuit.

- 230V Иштетүү: Use a dedicated 30A circuit.

3. Gas Connection (MIG/TIG)

For MIG and TIG welding, connect the appropriate shielding gas cylinder (e.g., Argon, C25) to the regulator provided. Attach the gas hose from the regulator to the gas inlet on the rear of the welder.

4. Welding Lead Connections

Жерди туташтырыңыз clamp to the appropriate terminal on the welder and secure it to the workpiece. Connect the MIG gun, TIG torch, or electrode holder to their respective terminals as required for the chosen welding process.

2-сүрөт: Жогортон ылдый view of the ESAB EMP 210 welder, highlighting its compact design and integrated handle for portability. This perspective shows the overall form factor of the unit, which is designed for easy transport and setup.

Иштөө нускамалары

The ESAB EMP 210 offers MIG, Stick (MMA), and TIG (Lift TIG) welding capabilities. Select the desired process using the control panel.

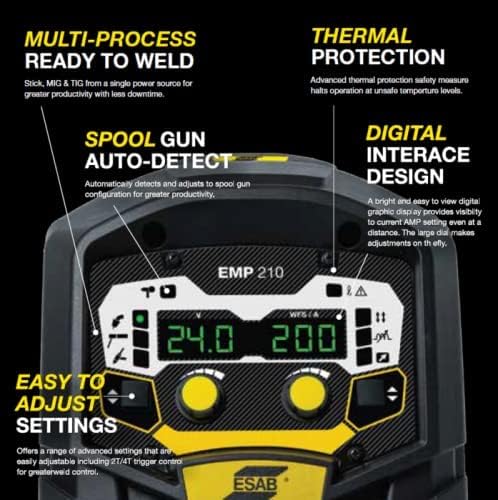

3-сүрөт: Деталдаштырылган view of the ESAB EMP 210's digital control panel. This image shows the clear display for voltagд жана amperage, along with the intuitive adjustment knobs and process selection buttons, emphasizing the "Digital Interface Design" and "Easy to Adjust Settings" features.

1. Control Panel Overview

The digital interface allows for precise control over welding parameters. Use the large dial and buttons to navigate menus and adjust settings such as ampэраж, тtage, and wire feed speed.

2. MIG Welding (GMAW)

- Install the appropriate welding wire spool and feed it through the MIG gun.

- Select MIG mode on the control panel.

- Көлөмдү тууралооtage and wire feed speed according to the material thickness and wire type.

- Ensure gas flow is set correctly (typically 15-25 CFH for solid wire).

3. Stick Welding (MMA/SMAW)

- Connect the electrode holder and ground clamp.

- Select Stick mode.

- Insert the appropriate electrode into the holder.

- Тууралоо amperage based on electrode type and diameter.

4. TIG Welding (GTAW - Lift TIG)

- TIG фонаригин жана жерге туташтыргычты туташтырыңызamp.

- TIG режимин тандаңыз.

- Ensure pure argon shielding gas is connected and flowing.

- Тууралоо amperage for the material and tungsten electrode size.

- Initiate arc using the Lift TIG method.

4-сүрөт: An individual performing welding operations with the ESAB EMP 210 Multi-Process Welder. The welder is visible in the background, and the operator is focused on the workpiece, demonstrating the machine in an active work environment.

Техникалык тейлөө

Regular maintenance ensures the longevity and optimal performance of your ESAB EMP 210 welder.

- Күнүмдүк: Clean the MIG gun nozzle, contact tip, and diffuser. Check ground clamp жана кабелдик байланыштар.

- Апталык/Айлык: Inspect all cables for damage. Clean the wire feed mechanism. Check gas hose for leaks.

- Мезгил-мезгили менен: Use compressed air to blow dust and debris from inside the machine (ensure power is disconnected). Inspect cooling fan for obstructions.

- Replace worn consumables (contact tips, nozzles, electrodes, tungsten) as needed.

Проблемаларды чечүү

Refer to the following table for common issues and their potential solutions. If a problem persists, contact ESAB customer support.

| Көйгөй | Мүмкүн себеп | Чечим |

|---|---|---|

| Арк жок | No power, poor ground connection, incorrect settings, faulty torch/electrode holder. | Check power supply, ensure solid ground, verify settings, inspect connections. |

| Ширетүү сапаты начар | Incorrect settings, contaminated material, improper technique, worn consumables. | Adjust parameters, clean workpiece, review technique, replace consumables. |

| Wire Feeding Issues (MIG) | Incorrect tension, clogged liner, wrong contact tip, tangled wire. | Adjust drive roll tension, clean/replace liner, use correct contact tip, untangle wire. |

| Overheating (Thermal Protection) | Exceeding duty cycle, poor ventilation. | Allow machine to cool, ensure adequate airflow around the unit. |

Техникалык шарттар

| Өзгөчөлүк | Деталь |

|---|---|

| Бренд | ESAB |

| Модель номери | 0324-0075 (EMP 210) |

| Киргизүү көлөмүtage | 120V / 230V DC (Автоматтык сезүү) |

| Ширетүү процесстери | MIG (GMAW), Stick (MMA/SMAW), TIG (GTAW - Lift TIG) |

| Max Чыгуу Ток | 200A |

| Элемент Салмагы | 43 фунт |

| Продукциянын өлчөмдөрү | 23 x 18.5 x 18 дюйм |

| Дата биринчи жеткиликтүү | 28-октябрь, 2021-жыл |

Кепилдик жана колдоо

Кепилдик маалымат

For detailed warranty terms and conditions, please refer to the official ESAB warranty statement included with your product or visit the official ESAB webсайт. Кепилдик, адатта, сатып алынган күндөн тартып белгилүү бир мезгил ичиндеги материалдардын жана жасалгалоодогу кемчиликтерди камтыйт.

Кардарларды колдоо

If you encounter any issues or have questions regarding your ESAB EMP 210 welder, please contact ESAB customer support. You can find contact information on the official ESAB webсайты же ыйгарым укуктуу дилериңиз аркылуу.

ESAB расмий өкүлү Webсайт: www.esab.com